The laboratories of Stazione Sperimentale del Vetro have the most complete instrumentation for the mechanical characterization of flat glass products used in the building and transport sectors. Our expert technicians can support the glass industry in the choice of the most appropriate standardised test methods, in the possible definition of custom test procedures, and in the interpretation of analytical results.

The laboratories of Stazione Sperimentale del Vetro have the most complete instrumentation for the mechanical characterization of flat glass products used in the building and transport sectors. Our expert technicians can support the glass industry in the choice of the most appropriate standardised test methods, in the possible definition of custom test procedures, and in the interpretation of analytical results.

Owing to the fragile nature of glass, the evaluation of the reliability and mechanical resistance of the products must be carried out on a sufficiently representative statistical sample.

The Axe test is typically performed on laminated glasses designed for anti-burglary applications, and involves the use of an electromechanical instrumented bench for the simulation of repeated blows with percussion tools (hammer, axe). The purpose of the test is to determine the specific class of resistance of an object made up of a certain stratification of glass panes, expressing it following the coding outlined by the EN 356 standard.

Tests are normally required for the verification of safety glass elements with anti-intrusion performance.

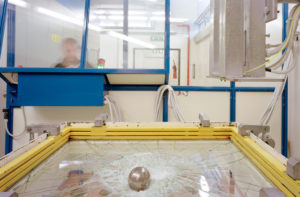

The Steel ball drop test simulates a vandalism act aimed at piercing the glass pane, and is performed by repeatedly dropping hardened steel balls of standard diameter from pre-determined heights onto the glass test specimen, clamped in place witihin a dedicated enclosure.

The result of the test is the determination of a class of resistance according to the code provided by the EN 356 reference standard.

The Pendulum test simulates the effect of an accidental impact on a glazing unit. It is performed by means of a pendulum consisting of two weighted wheels having a total mass of 50 kg, that is left to swing against the clamped test specimen from different calibrated heights.

The purpose of the test is to classify a glazed element with respect to the coding specified by the EN 12600 standard: in particular, the test defines whether a laminated glass can be considered a “safety glass”.

SSV is equipped with mechanical and hydraulic presses capable of carrying out 4-point bending tests or double concentric ring bending tests on any type of glass (annealed, toughened, laminated), in accordance with the EN 1288 – 3 and EN 1288 -5 standards.

This is a non-destructive test that, by exploiting the physical phenomenon of birefringence (photoelasticity), allows the determination and study of the residual stresses present in a given glass.

SSV is equipped with optical and digital instruments for measuring the surface compression of thermally or chemically strengthened or toughened glasses.

The test defines whether toughened glass can be considered “safety glass”.

Test is performed on heat-treated glass in accordance with the main European standards.

The determination of the compressive or tensile strength of the polymeric materials used as sealants in insulating glazing units is carried out using a dedicated mechanical press, following the EN 1279-4 reference standard.

SSV can develop dedicated testing protocols for the verification of glazing elements directly on-site, e.g. for parapets, floors, etc, with reference to existing technical standards or according to load cycles built on purpose.

In addition to the application of the loads foreseen by the test method, deformation/displacement measurements are carried out to verify the conformity to the expected behavior.