Thermally toughened flat glass can undergo phenomena of spontaneous breakage during service life due to the presence of inclusions of Nickel Sulfide (NiS) deriving from the float glass production process.

Thermally toughened flat glass can undergo phenomena of spontaneous breakage during service life due to the presence of inclusions of Nickel Sulfide (NiS) deriving from the float glass production process.

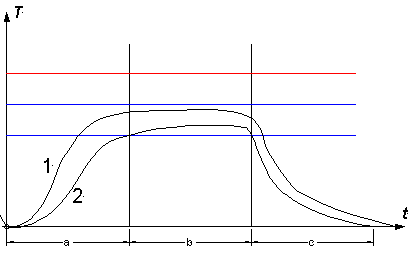

In order to reduce the risk of such phenomena, a post-toughening thermal process called “Heat Soak Test” (HST) is carried out on all the glasses intended for use (proof testing of the entire batch): if NiS inclusions are present in the samples, the HST heat treatment causes the breakage of the sheet and therefore leads to the elimination of all faulty products. Glasses that pass the test have a greatly reduced residual risk of spontaneous fracture (in the absence of external damage) during service life.

As specified by the EN 14179 standard, the full effectiveness of the HST process can be guaranteed only through periodic verification of the distribution of process temperatures within the HST furnace: SSV can perform such calibrations on site using its specific instruments.